When it comes to plastic films, there are two popular options in the market: HDPE (High-Density Polyethylene) and LDPE (Low-Density Polyethylene). Both materials are commonly used in packaging, agriculture, and construction industries. However, many consumers and businesses often wonder which is better between HDPE and LDPE. In this article, we will explore the differences between the two materials and discuss their respective advantages and disadvantages.

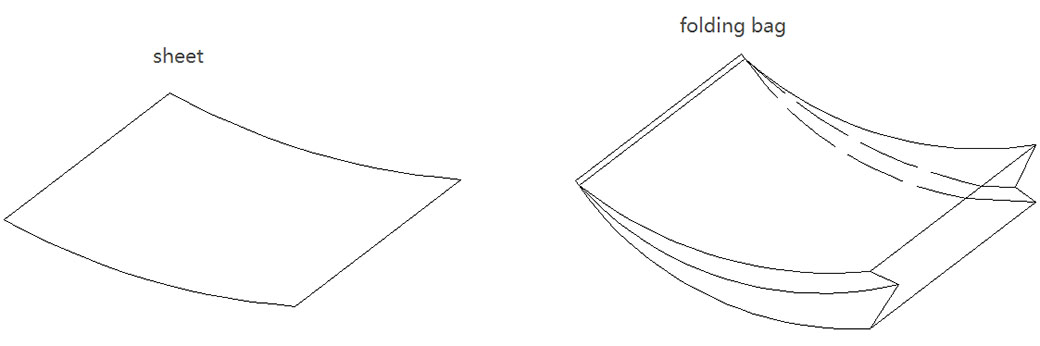

Firstly, let's take a look at LDPE. LDPE is a flexible and lightweight material that is commonly used in making thin and stretchy plastic films. LDPE is often used for packaging purposes, such as producing plastic bags, shrink wraps, and agricultural films. LDPE is known for its excellent resistance to moisture and chemicals, making it suitable for applications that require a high level of flexibility and durability. LDPE film manufacturers often produce a wide range of products to meet the diverse needs of their clients.

On the other hand, HDPE is a denser and stronger material compared to LDPE. HDPE is commonly used in applications that require rigid and durable plastic films, such as in the production of heavy-duty bags, tarpaulins, and industrial liners. HDPE plastic film is known for its excellent tensile strength and resistance to chemicals, making it an ideal choice for outdoor and heavy-duty applications. HDPE film manufacturers produce a wide range of products that cater to industrial and commercial applications.

Now, let's compare the two materials in terms of their properties and characteristics. LDPE is known for its flexibility and elasticity, which makes it suitable for applications that require stretchability and conformability to the products being packaged. On the other hand, HDPE is known for its rigidity and toughness, which makes it suitable for applications that require strength and durability. When it comes to chemical resistance, both LDPE and HDPE exhibit good resistance to moisture and chemicals, making them suitable for packaging and containment applications.

In terms of environmental impact, both LDPE and HDPE are recyclable materials. However, HDPE is commonly accepted for recycling in more communities compared to LDPE. This is because HDPE has a higher value in the recycling market due to its stronger and more rigid properties. As a result, HDPE is often preferred by environmental advocates and sustainability-conscious consumers.

In conclusion, the choice between HDPE and LDPE ultimately depends on the specific requirements and applications of the user. LDPE is ideal for applications that require flexibility and stretchability, while HDPE is suitable for applications that require rigidity and strength. Both materials have their own set of advantages and disadvantages, and it is important for businesses and consumers to consult with LDPE and HDPE plastic film manufacturers to determine the best material for their specific needs. Ultimately, both materials play a significant role in meeting the diverse needs of packaging, agriculture, and construction industries.

Post time: Feb-29-2024