LDPE, or low-density polyethylene, is a popular plastic used in a variety of products, including packaging. LDPE is known for its flexibility, strength, and clarity, making it an excellent choice for many different applications. One of the most common forms of LDPE is LDPE heat shrink film, which is widely used in the packaging industry. If you are interested in learning more about how LDPE is manufactured and the role of LDPE film manufacturers in this process, keep reading.

The manufacturing process of LDPE begins with the extraction of ethylene (a hydrocarbon gas) from natural gas or naphtha. After ethylene is obtained, it undergoes a process called polymerization, which involves joining many ethylene molecules together to form long chains of LDPE. The polymerization process can be carried out by different methods, including high-pressure polymerization or free radical polymerization, which is commonly used to produce LDPE.

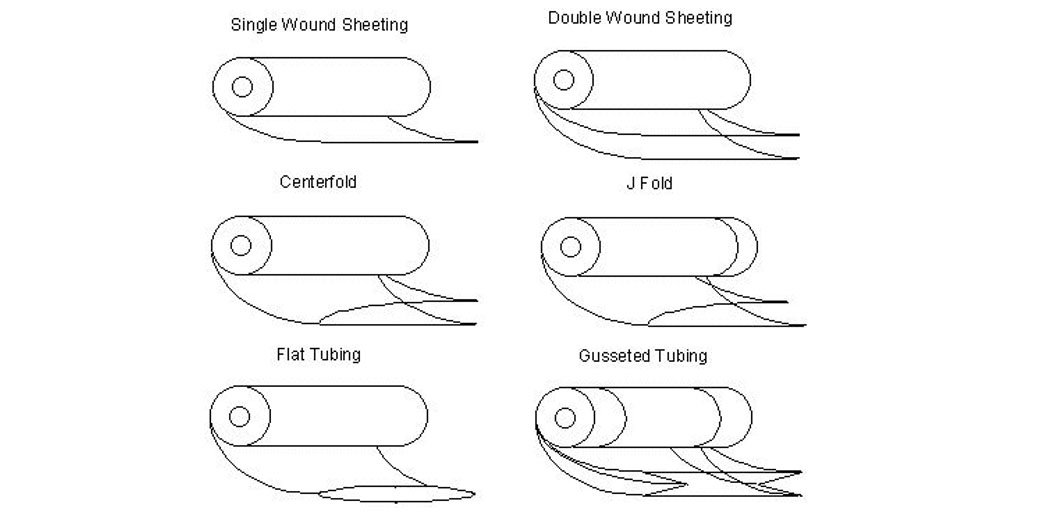

After the polymerization process, the LDPE is then melted and formed into the desired shape, such as film, through a process called extrusion. LDPE heat shrink film, in particular, is produced using a specialized form of extrusion called blown film extrusion. In this process, the LDPE is melted and forced through a circular die, which creates a tube of the molten plastic. The tube is then inflated, or "blown," with air to stretch and shape it into the desired thickness and width. The film is then cooled and wound onto large rolls for further processing and distribution.

Once the LDPE film is produced, it is typically sold to LDPE film manufacturers, who may further process the material and convert it into various types of packaging products, including heat shrink film. LDPE film manufacturers play a critical role in the manufacturing process by providing value-added services, such as printing, laminating, and converting the LDPE film into finished products that meet the specific needs of their customers.

In addition to the manufacturing and processing of LDPE film, LDPE film manufacturers are also responsible for ensuring the quality and consistency of the material. This involves conducting thorough testing and quality control measures to ensure that the LDPE film meets the necessary specifications and standards for its intended use. LDPE film manufacturers may also work closely with their customers to provide technical expertise and support, helping them to select the right type of LDPE film for their packaging needs.

In conclusion, LDPE is a versatile and widely used plastic material that is manufactured through a process of polymerization and extrusion. LDPE film manufacturers play a crucial role in the production and processing of LDPE film, including the manufacturing of LDPE heat shrink film. By providing value-added services and ensuring the quality of the material, LDPE film manufacturers contribute to the efficient and high-quality production of LDPE packaging products. If you are in need of LDPE film for your packaging needs, be sure to partner with a reputable LDPE film manufacturer who can meet your specific requirements.

Post time: Feb-27-2024