Discountable price Black Polythene Plastic Sheeting - Clear and white mdo shrink film factory certificated By SGS – SINO

Discountable price Black Polythene Plastic Sheeting - Clear and white mdo shrink film factory certificated By SGS – SINO Detail:

Product Description

The benefits of MDO technology are numerous. The process enhances the qualities of the film as a packing material, and reduces immediate costs by stretching it, sometimes by more than 1,000%.

Of course this results in a host of knock-on advantages: less raw material is used, leading to reduced mass and lower transportation costs. Perhaps best of all, MDO film can improve your company’s green credentials by shrinking your carbon footprint.

But it’s not just about the bottom line, because the MDO process produces a superior product. Stretched film exhibits greatly enhanced optical properties, which can be tailored to your requirements.

If you require a film with low or high gloss, polarisation or haze, these options are achievable by scaling the MDO machine settings. Film treated in this way also has better mechanical properties such as improved puncture resistance and easy tearing in a particular direction ruses of MDO technology.

Because the process also confers resistance to moisture, MDO products are not only used as packing materials, but as the impermeable layer in nappies, sanitary products and incontinence pads.

Some of the films are even made from natural biodegradable compounds.

Despite these applications, the manufacturing process is challenging. It consists of four separate stages, and selecting the wrong settings at any one of them can produce a film that is too brittle. MDO sounds simple, but works profound changes on the properties of the material treated manufacturing process of MDO film.

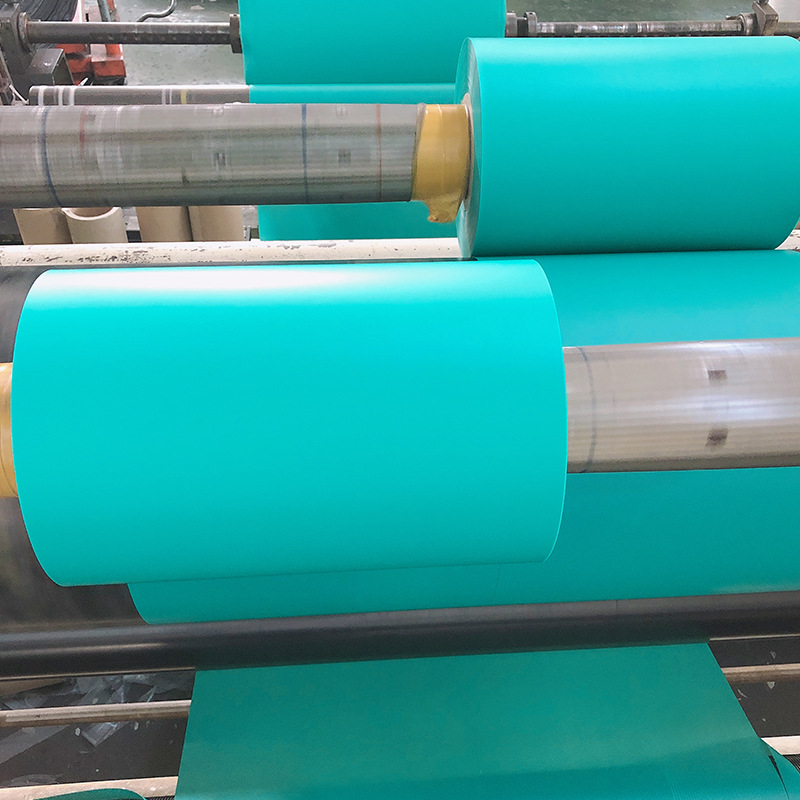

1. The first step in the MDO process is preheating, where a film is fed into the stretching unit and evenly warmed to the desired temperature.

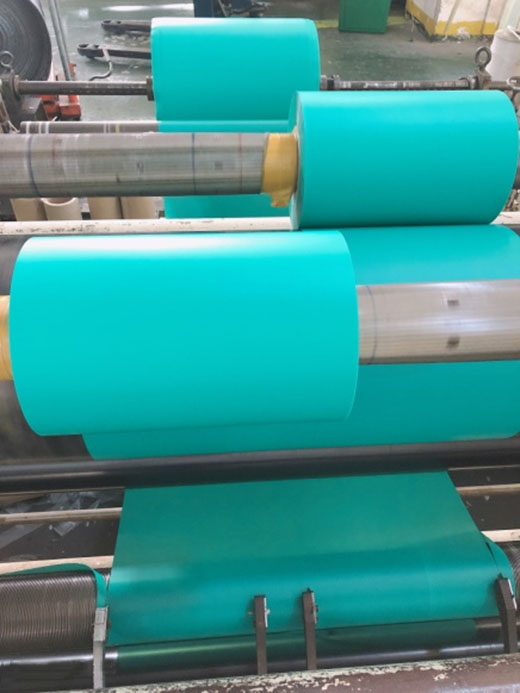

2. This is followed by orientation, where the film is stretched between a series of rollers that are revolving at different speeds.

3. Next, during the annealing stage, the film’s new properties are locked in and made permanent.

4. Finally it is cooled, when the film is brought back to near room temperature.

Execution

Width

| Tubular film | 400-1500mm |

| Film | 20-3000mm |

Thickness

0.01-0.8mm

Cores

Paper cores with inside φ76mm and 152mm.

Plastic cores with insideφ76mm.

Outside winding diameter

Max.1200mm

Roll weight

5-1000kg

Application

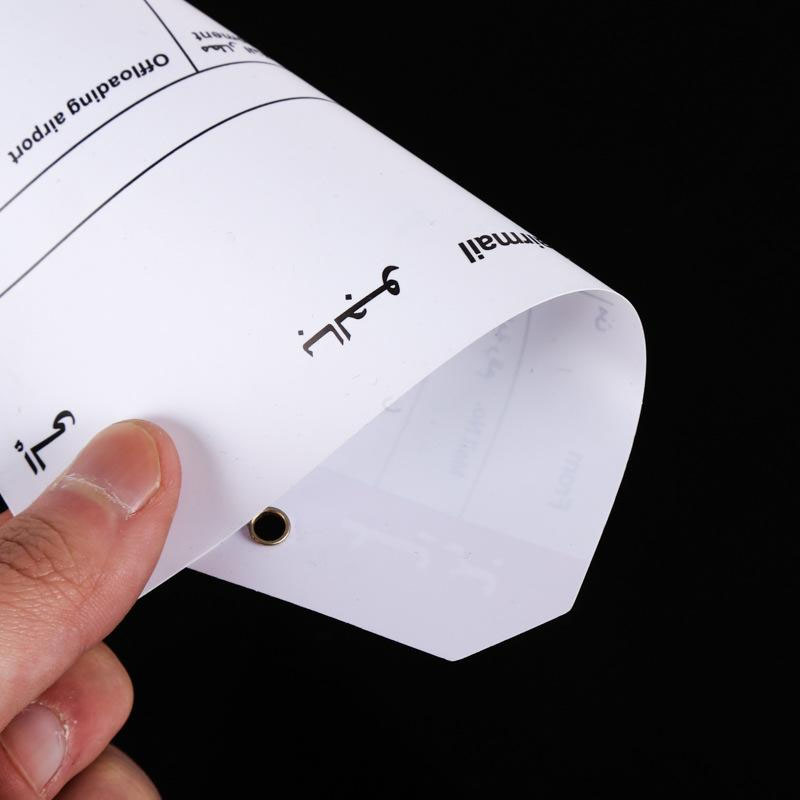

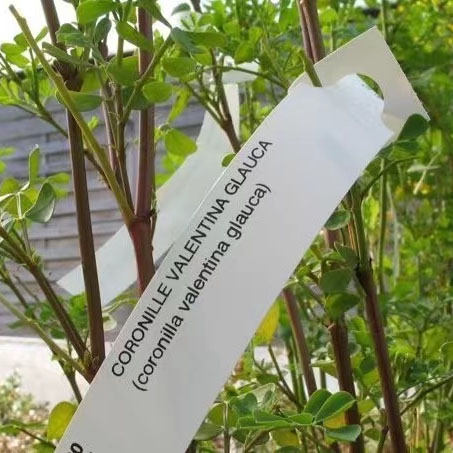

All kinds of logistics labels, self-adhesive label substrates, Load-bearing handle belt (rope), contract bag (FFS), vertical packaging.

HDPE packing film

HDPE co-extruded film

PE Label

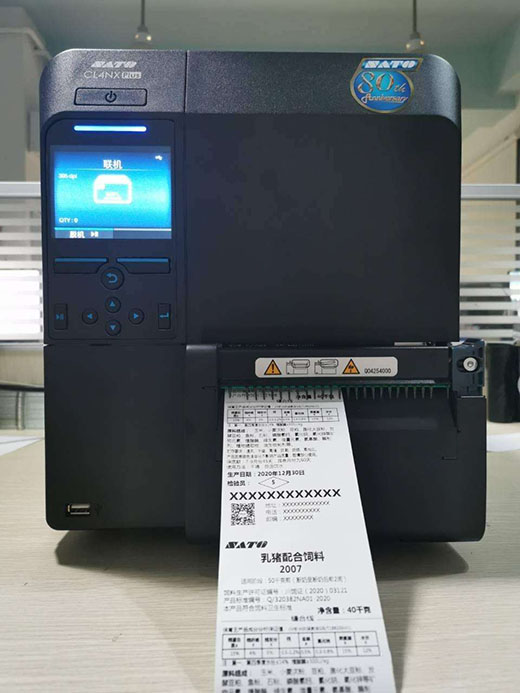

Product detail pictures:

Related Product Guide:

We usually believe that one's character decides products' high quality, the details decides products' excellent ,with the REALISTIC,EFFICIENT AND INNOVATIVE staff spirit for Discountable price Black Polythene Plastic Sheeting - Clear and white mdo shrink film factory certificated By SGS – SINO , The product will supply to all over the world, such as: Puerto Rico, Bolivia, panama, We'll continue to devote ourselves to market & product development and build a well-knit service to our customer to create a more prosperous future. Please contact us today to find out how we can work together.

The factory can meet continuously developing economic and market needs, so that their products are widely recognized and trusted, and that's why we chose this company.