Big Discount Sublimation Shrink Film - Nylon bag seven layer coextrusion film nylon composite film – SINO

Big Discount Sublimation Shrink Film - Nylon bag seven layer coextrusion film nylon composite film – SINO Detail:

Product Description

Vacuum nylon packaging bags can be divided into non barrier vacuum bags, medium barrier vacuum bags and high barrier vacuum bags from the barrier performance. In terms of functionality, it can be divided into low temperature resistant vacuum bags, high temperature resistant vacuum bags, puncture resistant vacuum bags, shrink bags, self-supporting bags and zipper bags. Because different products have different requirements for packaging materials, material selection should be made according to product characteristics, including: whether it is easy to deteriorate, factors leading to deterioration (light, water or oxygen, etc.), product form, product surface hardness, storage conditions, sterilization temperature, etc. A good vacuum bag does not have to have many functions, but depends on whether it is suitable for the product.

For products with regular shape or soft surface, such as sausage products, bean products, etc., it is not necessary to require high mechanical strength of the material, but only need to consider the barrier property of the material and the impact of sterilization temperature on the material. Therefore, for such products, opa/pe structure packaging bags are generally used. If high temperature sterilization (above 100 ℃) is required, opa/cpp structure can be used, or high temperature resistant PE can be used as the heat sealing layer.

Execution

Width

| Tubular film | 400-1500mm |

| Film | 20-3000mm |

Thickness

0.01-0.8mm

Cores

Paper cores with inside φ76mm and 152mm.

Plastic cores with insideφ76mm.

Outside winding diameter

Max.1200mm

Product use

Vacuum packaging of dry food, etc.

Product details

Nylon vacuum bag is resistant to oil, humidity, high temperature cooking at 90 ℃, low temperature freezing, quality assurance, fresh preservation and odor.

Application

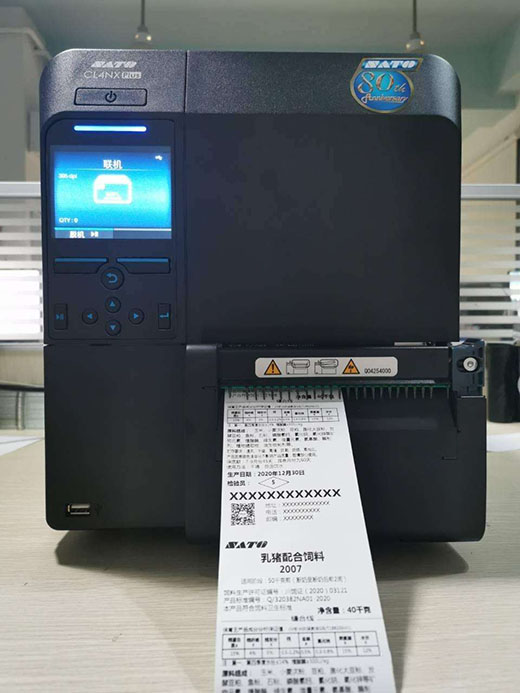

HDPE packing film

HDPE co-extruded film

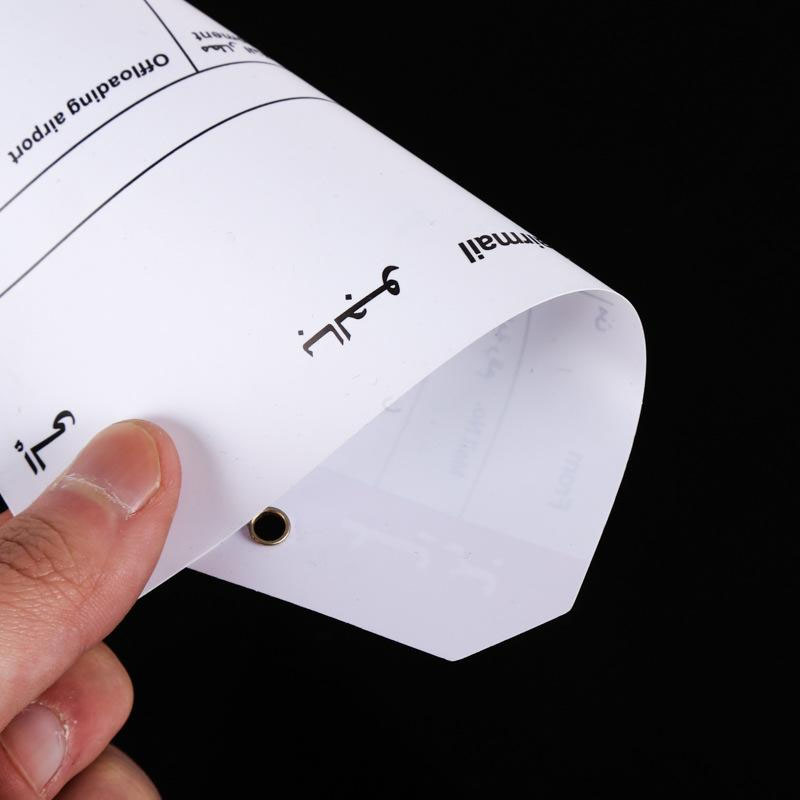

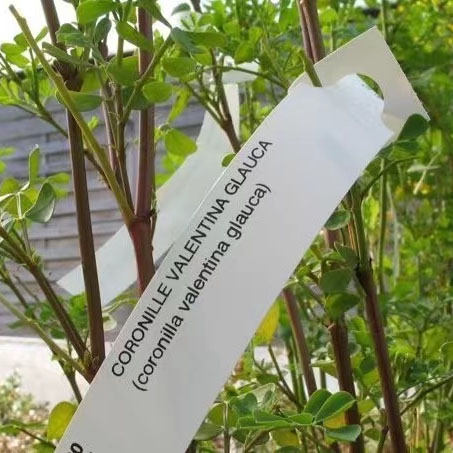

PE Label

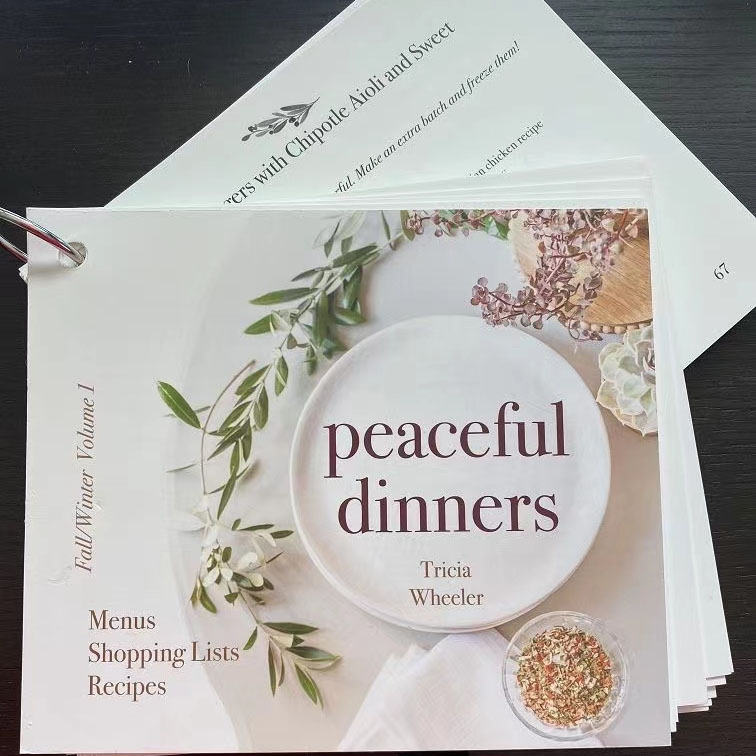

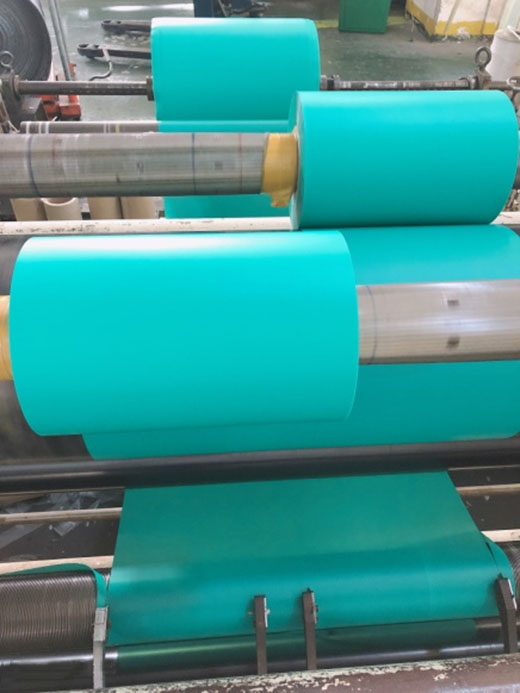

Product detail pictures:

Related Product Guide:

"Quality initial, Honesty as base, Sincere support and mutual profit" is our idea, so as to build repeatedly and pursue the excellence for Big Discount Sublimation Shrink Film - Nylon bag seven layer coextrusion film nylon composite film – SINO , The product will supply to all over the world, such as: Senegal, Morocco, Mombasa, Our company has always insisted on the business principle of "Quality, Honest, and Customer First" by which we have won the trust of clients both from at home and abroad. If you are interested in our products, please do not hesitate to contact us for further information.

Problems can be quickly and effectively resolved, it is worth to be trust and working together.